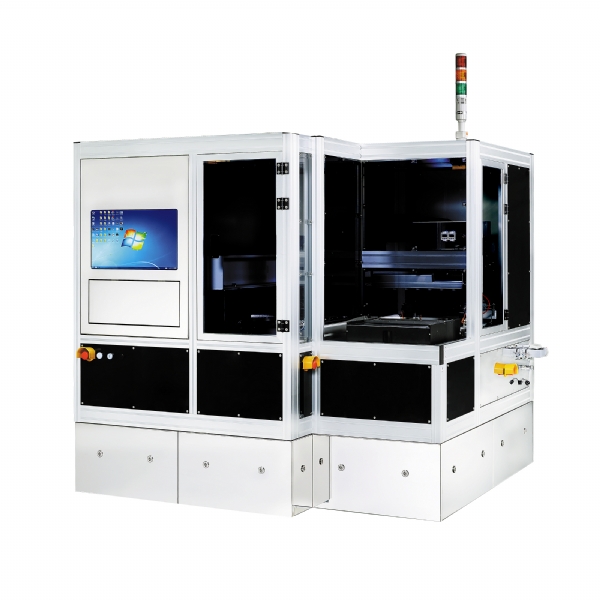

型號:DSI-3000

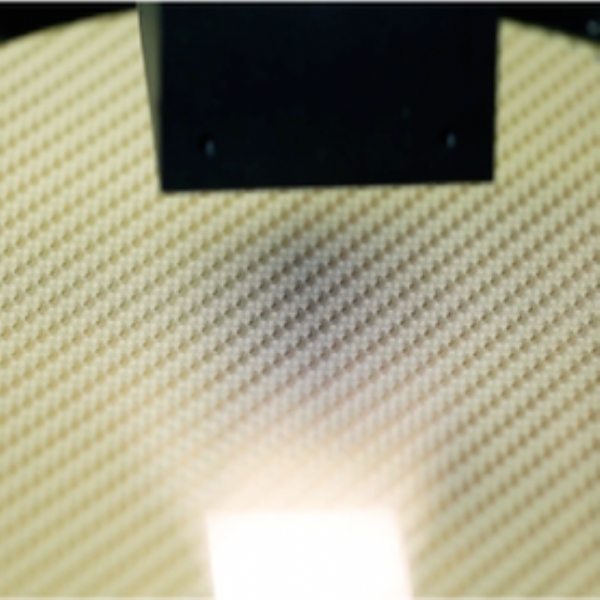

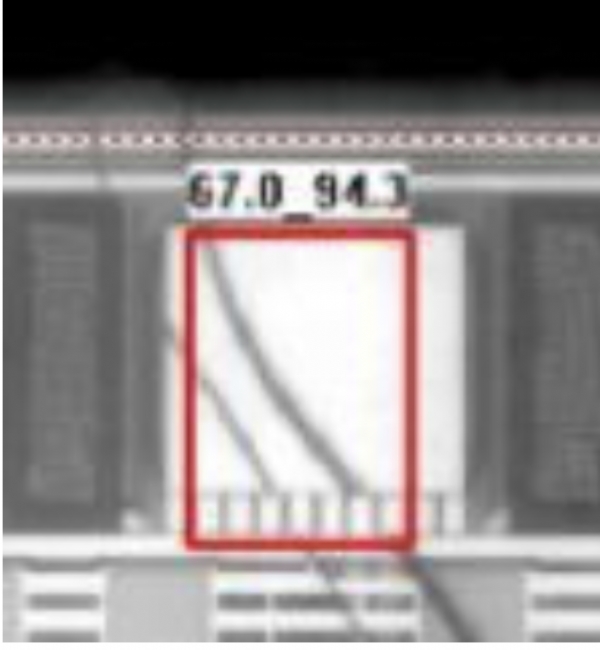

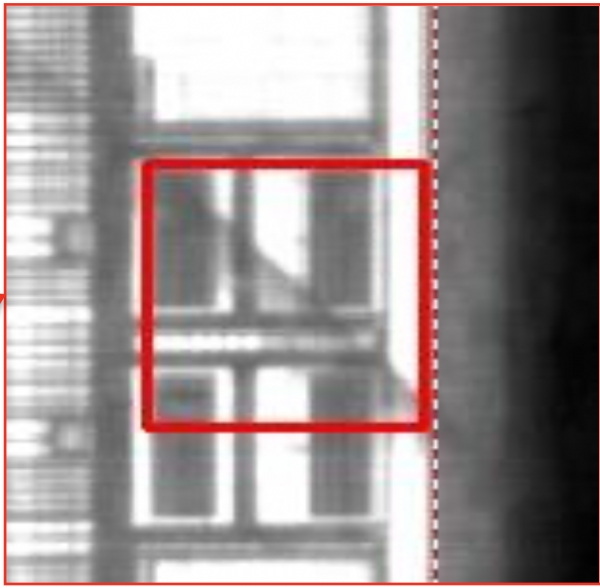

針對半導體晶圓切割(die saw)後造成的背崩和隱崩等缺陷做檢測,全自動的晶圓紅外線檢查機可自動的檢測出異常缺陷,降低了人為判斷的不確定性與時效性,且不須挑die(pick & place)即可檢測,提升產品品質的管控,也提供wafer mapping,缺陷影像輸出及統計資訊...等功能。

針對半導體晶圓切割(die saw)後造成的背崩和隱崩等缺陷做檢測,全自動的晶圓紅外線檢查機可自動的檢測出異常缺陷,降低了人為判斷的不確定性與時效性,且不須挑die(pick & place)即可檢測,提升產品品質的管控,也提供wafer mapping,缺陷影像輸出及統計資訊...等功能。